Trailer Wiring Schematics are essential blueprints that outline the electrical connections of a trailer. They are crucial for ensuring that all electrical components of a trailer function properly and safely. Understanding and interpreting these schematics is vital for anyone working on trailers or troubleshooting electrical issues.

Importance of Trailer Wiring Schematics

Trailer Wiring Schematics are essential for the following reasons:

- Ensure proper functioning of trailer lights, brakes, and other electrical components.

- Help in diagnosing and fixing electrical issues quickly and accurately.

- Ensure compliance with safety regulations and standards.

- Prevent electrical failures and hazards while towing a trailer.

Reading and Interpreting Trailer Wiring Schematics

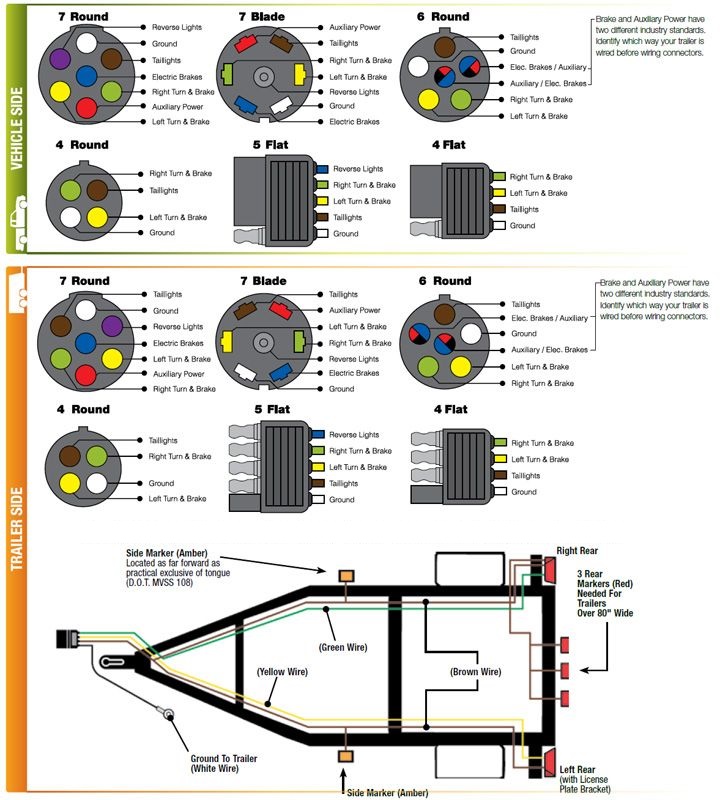

Reading and interpreting Trailer Wiring Schematics may seem daunting at first, but with some guidance, it can become easier:

- Start by understanding the symbols and abbreviations used in the schematic.

- Follow the lines and connections to identify how different components are wired together.

- Pay attention to color-coding and labeling of wires for easier identification.

- Refer to the legend or key provided with the schematic for additional information.

Using Trailer Wiring Schematics for Troubleshooting

Trailer Wiring Schematics are invaluable tools for troubleshooting electrical problems in trailers:

- Identify the specific circuit or component causing the issue on the schematic.

- Trace the wiring to locate any breaks, shorts, or faulty connections.

- Compare the schematic with the actual wiring to pinpoint the problem accurately.

- Refer to technical manuals or guides for additional troubleshooting tips and solutions.

Safety Tips and Best Practices

When working with electrical systems and using wiring diagrams, safety should always be a top priority:

- Disconnect the trailer from the power source before starting any work on the electrical system.

- Use insulated tools to prevent electrical shocks and short circuits.

- Wear appropriate personal protective equipment, such as gloves and safety goggles.

- Follow manufacturer’s instructions and guidelines for proper handling of electrical components.

Trailer Wiring Schematics

7 Plug Trailer Wiring Schematic

Cam Line Trailer Wiring Diagram

Trailer Wiring Diagram | Buy Enclosed Cargo Trailers at Clarklake

Wiring Diagram For A Dump Trailer

trailer+wiring+schematics+and+pictures – Diagram Board

Car Trailer 7 Pin Wiring Diagram