Alternator Wiring Schematic plays a crucial role in understanding the electrical system of a vehicle. It provides a visual representation of how the alternator is wired to the battery and other components in the charging system. By studying the schematic, mechanics can diagnose issues, make repairs, and ensure that the electrical system is functioning properly.

Why Alternator Wiring Schematic are essential

Alternator Wiring Schematic are essential for several reasons:

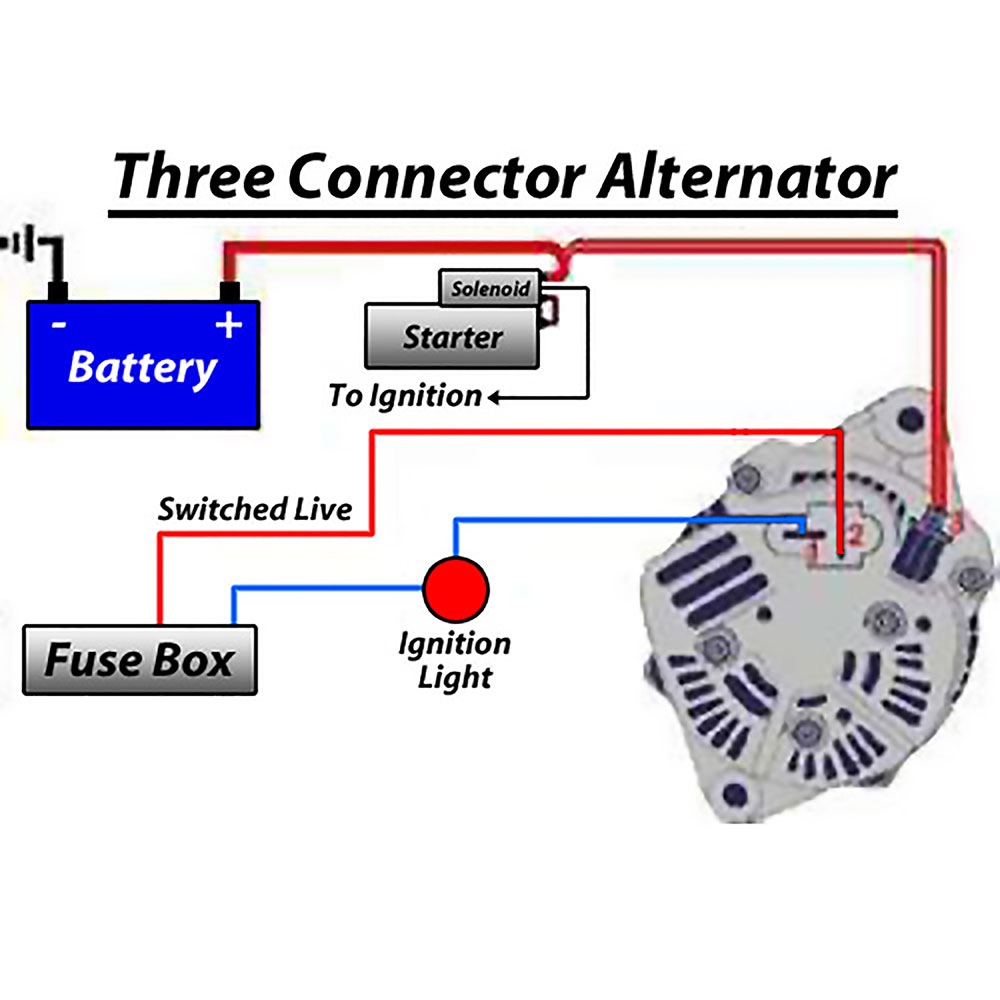

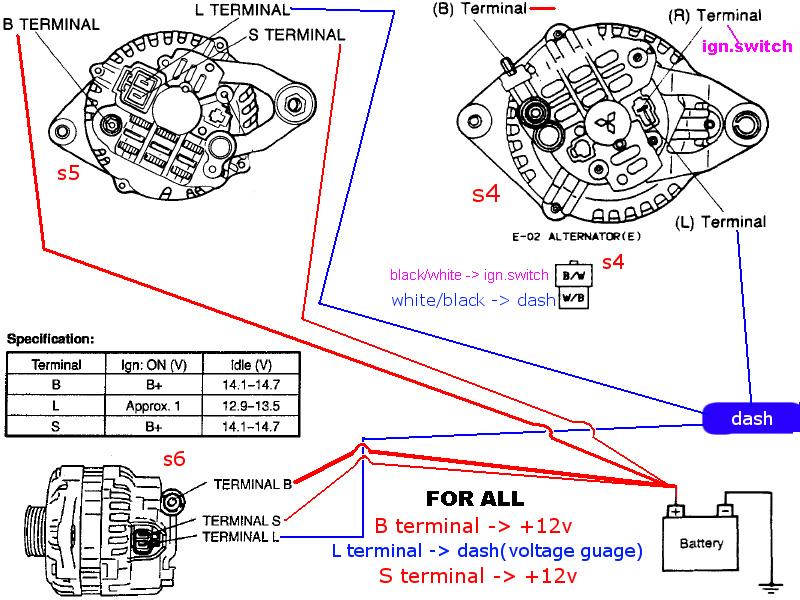

- They help mechanics understand the wiring connections between the alternator, battery, voltage regulator, and other electrical components.

- They provide information on wire colors, terminal locations, and the flow of electricity through the system.

- They serve as a roadmap for troubleshooting electrical problems and conducting repairs.

How to read and interpret Alternator Wiring Schematic effectively

Reading and interpreting Alternator Wiring Schematic can be daunting for beginners, but with practice and guidance, it becomes easier. Here are some tips:

- Start by familiarizing yourself with the symbols and abbreviations used in the schematic.

- Identify the key components, such as the alternator, battery, voltage regulator, and ground connections.

- Follow the flow of electricity from the alternator to the battery to understand how the system works.

Using Alternator Wiring Schematic for troubleshooting electrical problems

Alternator Wiring Schematic are invaluable tools for diagnosing and fixing electrical issues in a vehicle. Here’s how you can use them effectively:

- Trace the wiring diagram to locate any loose connections, damaged wires, or faulty components.

- Check for continuity and voltage at key points in the system to identify where the problem lies.

- Compare the schematic to the actual wiring in the vehicle to ensure they match up correctly.

It’s important to exercise caution when working with electrical systems and using Alternator Wiring Schematic. Here are some safety tips to keep in mind:

- Always disconnect the battery before working on the electrical system to prevent electrical shock or short circuits.

- Use insulated tools and wear protective gear, such as gloves and goggles, when handling electrical components.

- Double-check your work and consult the schematic regularly to avoid mistakes and ensure proper wiring connections.

Alternator Wiring Schematic

Common Delco SI Series Alternator Wiring Diagram | Smith Co Electric

Alternator Wiring Diagram For The Battery Alternator Car – Floyd Wired

Auto Alternator Wiring Diagram

Alternator Wiring Diagram Chevy 350

Wiring An Alternator Diagram

Alternator To Motor Wiring Diagram